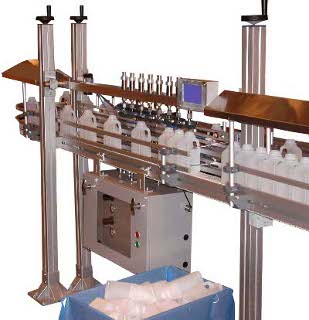

LTU5000 Conveyor-Fed Bottle Leak Detector

Single- or Multi-head conveyor fed machine for high speed bottle leak detection.

8-Channel LTU5000 system testing bottles at 140 per minute.

8-Channel LTU5000 system testing bottles at 140 per minute.

Main Screen

Main Screen

"Counts screen - shows per-test head bottles counts"

"Counts screen - shows per-test head bottles counts"

General Description

The LTU5000 leak detector is an in-line bottle leak detection system capable of testing between 1 and 16 bottles at a time at rates up to 240 bottles per minute (depending on the configuration). Its intended use is for 100% leak testing of the output of a blow molding machine. Various options are available which allow the system to perform additional operations on the bottles.

Its reliability, accuracy, flexibility and high speed of operation makes it an extremely cost effective alternative to expensive rotary leak testers. No "change parts" are required.

Features

The LTU5000 series of leak testers have many advanced features:

High accuracy leakage measurement

The system uses a sensitive pressure transducer with a low noise amplifier and high speed, high resolution analog to digital converter. This minimizes measurement errors.

Flexible bottle transport system

Timings can be easily adjusted to optimize bottle transport, where required, without sacrificing test time.

New Touch-Screen Microprocessor control system

It is now cost effective to use a modern touch-screen operator interface, rather than a simple digital readout. This has many advantages as follows:

- Extremely flexible design. Extra features and customizations can be easily integrated into existing systems.

- All test results, displays and counts are displayed together on the main displays page. This enables evaluation of the status of the system at a glance.

- All settings are displayed together on a settings page, allowing easy inspection and modification.

- All input and output states are displayed together on a diagnostics page. This allows quick fault finding.

- The graphics based nature of the screen allows descriptive text and graphics to appear identifying all settings , results and warnings.

- Setting changes can be locked out if required.

- International - Since all information is presented on the touch screen display, it is easy to change the program to use another language (where the system is to be used in a non - English speaking country).

- USB Interface for firmware updates - allows software updates and new features to be sent via email

Compact CPU / Touchscreen. Program upgradeable via USB

Compact CPU / Touchscreen. Program upgradeable via USB

High Reliability

This is possible due to technology improvement, reduced component count, integration of all electrical functions onto the PCB, and an in-depth understanding of failure mechanisms.

Modular pneumatic system

State of the art pneumatic system - valves rated at 50 million cycles

State of the art pneumatic system - valves rated at 50 million cycles

- Allows quick customization for special needs.

- Allows easy expansion of system to include extra facilities even after installation.

Cost Effective

Up to 12 channels of leak detection on one circuit board

The circuit cards have been designed and programmed specifically for this application. Great care has been taken to ensure that the system is easily re-programmable, expandable and reliable. This means that the performance and cost limitations of using a bought-in Programmable Logic Controller are avoided.

Wide Range of Options

The leak tester design is highly flexible with respect to software, electronics, pneumatics and mechanics. This allows a wide range of options (see following) to be added at any time, even after installation.

5 Channel Leak Tester

Options

Extra Test Channels

It is straightforward to add additional test channels at any time, in order to increase throughput.

Choked Bore / Ovality Test

A probe fitted to the test head checks whether the neck is occluded or deformed.

Height Check

A fiber-optic sensor checks that the bottle is not too tall. This can detect folded over base flash on some bottles, as well as neck flash.

Auxiliary Sensors

Spare inputs are available which can be used to connect other sensors which examine the bottle during the leak test. Examples are label sensors, flash detection sensors or vision systems. The leak tester would fail the bottle if any of these inputs are triggered.

Fallen bottle detection & rejection

Fallen bottle detection & rejection

Bottle transport options

A variety of bottle transport options can be fitted to replace the standard method, for use with certain bottle types. Options include side clamps and holding moulds.

Stabilization Plate / Brush

A pneumatically operated mechanism can be fitted to the infeed of the leak tester. This is only required when the conveyor is to be fed directly from the output of a blow molding machine with violent take-out movements, and where the conveyor can not go inside the machine guard. The queue of bottles is supported by the plate when push-out occurs. The plate then opens, allowing the bottles to travel down the conveyor.

Batch Counter / Diverter

This is a simple system intended to assist the scramble packing of bottles. A diverter mechanism at the end of the conveyor allows bottles to go into one or the other of two boxes. A preset count is entered into the system. Each time the count is reached, the diverter changes state. The bottles fall into the new box while the previous box, now full, is taken away and replaced. An optional alarm and reset button is available to alert an operator.

Vacuum Operation

The system usually pressurizes the bottles during the leak test. However, it is possible to supply the system for vacuum operation where required.

Special test pressure

The system test pressure is adjustable over a limited range (see specification). If this range is not sufficient, a different transducer can be fitted to allow any test pressure desired.

Data logging / SPC

The standard system maintains counts of passed and failed bottles. More extensive data logging and SPC features can be implemented by exchanging the controller PCB for one with the SPC option fitted.

Infra Red Beam Wall Thickness Measurement

As the bottle travels along the conveyor, it passes through a modulated infra red light beam. The absorption of the beam is measured and used to test the wall thickness. This can be used to detect wall thickness variations, blown in necks, etc. The system was designed for natural plastic (e.g. milk bottles) but may be suitable for other applications.

Multi-Gate Scramble Packing System

This is an optional facility where the leak detector includes a box packing system suitable for scramble packing of bottles. Bottles are diverted off the main conveyor into packing cartons, at a number of stations. For more details refer to the product manual.

Specification

| Electrical Power Supply | 220/250 VAC single phase or 110/120 VAC Single Phase (specify when ordering) |

| Electrical Power consumption | 50 VA maximum |

| Air Supply | 4-10 bar |

| Air Consumption | 1 liter / minute typical |

| Minimum bottle volume | 250 ml |

| Maximum bottle volume | 10 liters. |

| Test Pressure | Adjustable, 10 - 40 mB. This range can easily be changed on request. |

| Cycle Time | 1.0 - 20.0 seconds, adjustable. |

| Hole Size Detected | See Graphs Below |

| Leak Test Method | Ratiometric Pressure Decay, Auto-zero, Auto-Scale. Adaptive pressurization algorithm. |

| Transducer | Semiconductor strain gauge diaphragm, 0.00 - 65.00 mB, 0.02% resolution, 20 x Over-pressure Protection. |

Performance Graphs

Following are some performance graphs showing the sensitivity (hole size detected) of the LT series of leak detectors. Each graph shows performance for a particular bottle size. Each model of leak tester (Single, Twin, Triple channel etc) has a line on the graph.

To use the graphs, first choose the graph nearest to the bottle size of interest (0.25 Liters, 0.5 Liters, etc, shown at the bottom). Look along the horizontal axis and find the Throughput (10,20,30 etc bottles per minute) required. Draw a line upward from this point until you reach a colored line. (The model of leak tester represented by this line is shown as the "Number of heads" table on the right.) Read off the Hole Size Detectable from the scale on the left. If this is more sensitive than that required, continue upwards to the next model.

The graphs shown are all for a single in line conveyor configuration. For a dual in line conveyor system, use half of the total throughput required to select the number of heads per side, e.g. for a 250 bottle per minute system, use 125 BPM to select the number of heads per side.

Remember to allow a margin of speed to allow the leak tester to catch up with the machine after a stoppage, or when manually feeding extra bottles onto the conveyor.

Notes on Performance Graphs

The graphs above are based on real-life figures as measured on a wide range of installations, machine configurations and bottle types. This data has been used to create a mathematical model which produced the smooth lines above (instead of a series of measured data points). Realistic values are assumed for the variables involved (conveyor speed, bottle dimensions, bottle stretch characteristics, leak tester accuracy). The sensitivity shown is conservative. However, it is possible that a particular application will encounter different values for these. For example, an unstable bottle may require a slower conveyor. We suggest that you contact the office before specifying a particular model of leak tester so that we can take all parameters into account.