Our Product Range

Overview of our product range

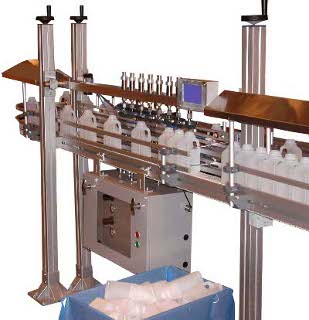

Conveyor Mounted Leak Detectors

These are bottle leak testers designed to be fed bottles on a continously moving conveyor. Reject bottles are ejected from the conveyor at a reject station immediately after the test area.

Models are available with throughputs up to 200 containers per minute. The machines can be supplied complete with conveyor, or alternatively as a kit to fit to an existing conveyor system.

A range of options are available to extend the tests performed, we are always willing to discuss specific test requirements.

Trimmer Mounted & In-Machine Leak Detectors

These are designed to be mounted on an indexing bottle trimmer, or for other in-machine use where the leak tester does not control bottle transport.

- LTU6000 & LTU6000H

- LTU2000 Replacement for 3rd party QT210F model

- LT2 (Legacy Product)

Manually Operated Leak Detectors

These are for use in static test fixtures, where an operator loads the part into a test fixture and presses a button to perform a test. Typically used for moulded parts where conveyor feed is not practical, such as fuel tanks or large drums.

Collating Tables

These are used at the end of a blow molding line to pack bottles.

Collating Table with Integrated Leak Detector

Also available with integrated leak detection...